RecyClass approves inks without nitrocellulose for flexible packaging

- Last update: 6 days ago

- 2 min read

- 9 Views

- HEALTH

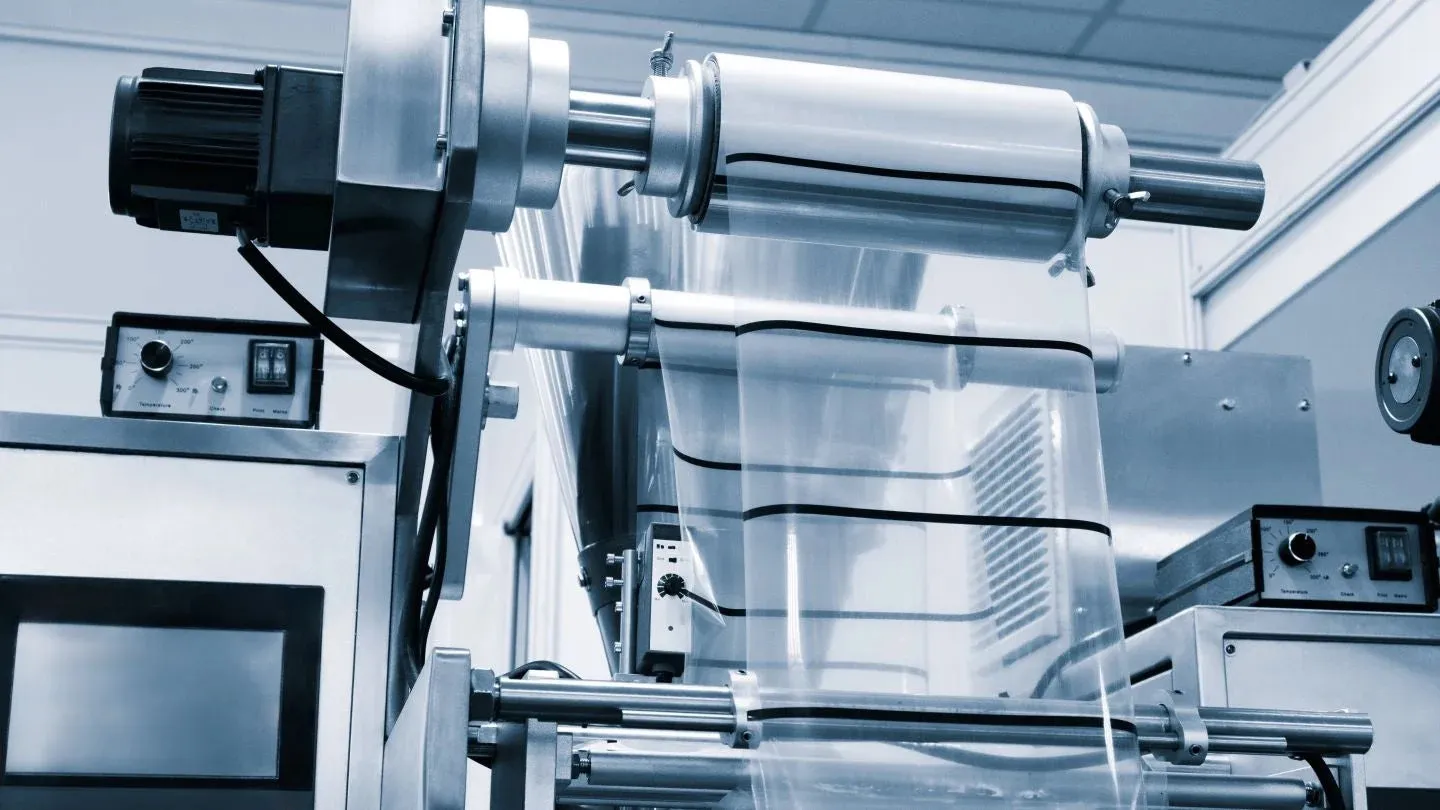

The pan-European initiative, RecyClass, has given its approval to a new series of nitrocellulose-free inks designed for both surface and reverse printing on flexible plastic packaging. This validation followed rigorous testing that confirmed these inks are fully compatible with existing polyethylene (PE) and polypropylene (PP) recycling processes.

RecyClass is recognised by the Circular Plastics Alliance as an official auditing body, assessing the recyclability and traceability of plastic materials. Its PO Films Technical Committee conducted an extensive test programme under the Recyclability Evaluation Protocol for PE films, evaluating four polyurethane (PU)-based inks and one acrylic-based alternative.

Results showed that the tested inks did not compromise the quality of recycled pellets or the properties of resulting films. No reduction in colour stability was observed, and volatile emissions remained unchanged during processing. Additionally, a polyvinyl butyral (PVB)-based ink sample demonstrated similar performance. Based on these findings, RecyClass confirmed that both PU and PVB inks are fully suitable for integration into current PE and PP recycling streams.

Following these results, RecyClass plans to update its Design for Recycling guidelines to incorporate the new recommendations. The organisation emphasized that ink coverage on packaging should not exceed 5% of total weight to minimise any potential impact on recyclability.

In other developments, GS Caltex has become the first Asian company to obtain RecyClass certification for its end-of-life vehicle plastics recycling system. By 2025, RecyClass anticipates its framework will encompass over 60% of the European plastics recycling sector and continue to serve as an international reference for circular plastics practices.

Author: Sophia Brooks

Share

Navigating the strangest winter virus season we've ever experienced

1 hours ago 3 min read HEALTH

General practitioners acknowledge feeling pressured to overdiagnose mental health problems

1 hours ago 2 min read HEALTH

RFK Jr. is reshaping public health messaging beyond vaccines

1 hours ago 4 min read HEALTH

Researchers Discover That This Basic Diet Improves Digestion and Enhances Gut Health

3 hours ago 3 min read HEALTH

Concerns arise over US childhood vaccine schedule following hepatitis B guideline revision

3 hours ago 3 min read HEALTH

The benefits of smelling your own farts according to science

3 hours ago 2 min read HEALTH

FDA approves Francis Medical's water vapor ablation treatment for prostate cancer

4 hours ago 2 min read HEALTH

Study finds bird flu gene enhances its ability to survive human fever defences

6 hours ago 4 min read HEALTH

Many lifters are making painful mistakes with the seemingly simple front rack position

6 hours ago 2 min read HEALTH

Singing along improves lung health and supports a charitable cause

9 hours ago 2 min read HEALTH